Type | Material | Acid value | Appearance | Recommended dosage | Note |

SYNLUB 1210 | Polymerized ester | 25 | Light yellow transparent liquid | 2~5% | High viscosity polymer ester, high oil film strength, can be used for cutting and heavy load machining, GY10 |

SYNLUB 1225 | Polymerized ester | 20 | Turbid viscous liquid | 2~5% | High viscosity polymer ester, high oil film strength, can be used for cutting and heavy load processing, high-cost performance in oily products, GY25 |

SYNLUB 1259 | Polymerized ester | 5 | Amber transparent liquid | 2~6% | Oil soluble lubricant, suitable for aluminum alloy processing, GY59 |

SYNLUB 310 | Polyalkylene derivatives | 10 | transparent liquid | 2~ 10% | Excellent extreme pressure performance and does not contain chlorine, phosphorus and sulfur. It can be dissolved in alkaline systems in any proportion without the addition of any couplant, low odor. MARLOX FS 40 |

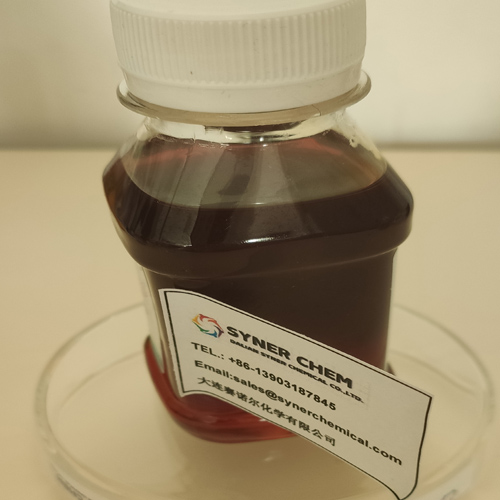

ESTER 935 | Self emulsifying ester | 45 | D-brown liquid | 2~5% | It can improve the boundary lubrication performance in fully synthetic and semi-synthetic formulas. It is an ideal substitute for polyether products. It has many effects, such as lubrication, emulsification, and hard water resistance.Priolube 3955 |

ESRER-943 | polyether ester | 35 | yellow transparent liquid | 3-10% | High-perrformance polyether ester with special structure, excellent lubricating properties can be used for a variety of harsh cutting and stamping processes, suitable for the preparation of metalworking fluids, water-soluble stamping fluids KL522 |

High viscosity polymer ester, high oil film strength, can be used for cutting and heavy load machining, GY10

High viscosity polymer ester, high oil film strength, can be used for cutting and heavy load processing, high cost performance in oily products,GY25

Oil soluble lubricant, suitable for aluminum alloy processing, GY59

Excellent extreme pressure performance and does not contain chlorine, phosphorus and sulfur. It can be dissolved in alkaline systems in any proportion without the addition of any couplant, low odor. MARLOX FS 40

It can improve the boundary lubrication performance in fully synthetic and semi synthetic formulas. It is an ideal substitute for polyether products. It has many effects, such as lubrication, emulsification, hard water resistance .Priolube 3955

High-performance polyether ester with special structure, excellent lubricating properties, can be used for a variety of harsh cutting and stamping processes, suitable for the preparation of metalworking fluids, water-soluble stamping fluids KL522

In order to meet customers’ requirements for formula stability and compatibility from our metalworking fluid, and to ensure the stability of our product quality, Syer Chem has increased investment in laboratory equipment.

As one-stop solution of metalworking fluid, below products you can find from us easily to improve you overal properties of your products.

Copper corrosion inhibitors for metalworking fluids protect copper and copper alloys from corrosion, ensuring the integrity and performance of metalworking processes involving these materials.

Corrosion inhibitors of ferrous metals are often called rust inhibitors or anti rust agent. In the process of processing different corrosion inhibitors need to be used different metal materials. We can customize corrosion inhibition products according to customer requirements.

Different emulsifiers can be used in the metalworking fluid to enhance lubrication, and ensure that the water and oil components remain well-mixed, enabling efficient heat transfer

White Corrosion Inhibitors for metalworking fluids play a crucial role in protecting metal surfaces from a specific form of corrosion known as “white rust.” These inhibitors are designed to address the challenges posed by galvanized surfaces and certain metals that are prone to this type of corrosion when in contact with metalworking fluids.

Extreme pressure agents (Anti-wear agent) for metalworking fluids form protective films on metal surfaces to withstand high pressures and temperatures during machining, reducing tool wear and improving process efficiency.

Specialty amines for metalworking fluids can act as corrosion inhibitors, pH buffers, or emulsifiers to enhance the performance and stability of the fluid.

Antioxidants in metalworking fluids prevent oxidation and degradation of the fluid, ensuring its stability and longevity.

Contact us right now to get more information, professional advice will be supplied within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.