Brief introduction:

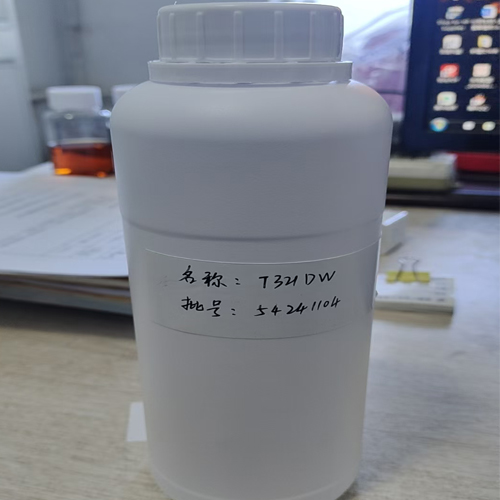

T321DW is also known as disobutylene sulfide and dihydrocarbyl pentasulfide. It has the characteristics of high active sulfur content, excellent extreme pressure performance, strong stability and good solubility. It is suitable for preparing metal working fluid and metal working oil.

Similar Product: Additin RC 2540; , Sulfurized Olefins S40

Chemical Name: Sulfurized Olefins

CAS No: 68515-88-8

Formula:C24h5OS8

Package: 200L/barrel, 1000L/IBC Tank

Item | Quality standards |

Appearance | Yellow liquid |

Moisture%(V/V) | ≤0.03 |

Mechanical impurities% | ≤0.05 |

Flash point (open)°C | ≥150 |

Kinematic viscosity (40°C)mm²/s | ≥30.0 |

Density (20°C)kg/m³ | 1000-1050 |

Oil solubility | Transparent, without precipitation |

Active sulfur % | 38 |

Sulfur content%(m/m) | 38-40 |

Copper corrosion (121°C, 3h level) | ≤4c |

Properties:

(1) Lubricating Properties

Sulfurized olefins T321DW have excellent lubricating capabilities. In metal – to – metal contact scenarios, they can form a lubricating film on the surface. This film reduces friction and wear, which is crucial for machinery with moving parts. For example, in metalworking operations like cutting and grinding, they help to extend the life of cutting tools and improve the surface finish of workpieces.

(2) Extreme – Pressure Resistance

Sulfurized olefins T321DW exhibit outstanding extreme – pressure (EP) resistance. In high – load and high – pressure environments, such as heavy – duty gear systems or metal – forming operations, Sulfurized olefins T321DW can withstand the extreme forces. The sulfur – based functional groups react under high pressure to form a protective layer that prevents metal surfaces from seizing or galling.

(3) Thermal Stability

Sulfurized olefins T321DW shows good thermal stability. It can maintain its chemical integrity and functional properties at relatively high temperatures. This is important in applications where heat is generated, such as in high – speed machining or high – power gearboxes. The compound does not decompose easily, ensuring consistent lubrication performance.

Applications

(1) Metalworking Fluids

In metalworking fluids, Sulfurized olefins T321DW are used as key additives. They improve the overall performance of the fluids by enhancing lubrication and anti – wear characteristics. This leads to better machining quality, higher cutting speeds, and reduced tool wear.

(2) Gear Oils

Gear oils formulated with Sulfurized olefins T321DW can provide excellent protection for gears. The extreme – pressure resistance and anti – wear properties of Sulfurized olefins T321DW help to prevent gear tooth wear, pitting, and scoring, especially in heavy – duty and high – speed gear applications.

(3) Hydraulic Fluids

In hydraulic systems, Sulfurized olefins T321DW can enhance the fluid’s ability to handle high pressures. They also contribute to reducing internal leakage by improving the seal – lubricating properties, ensuring the smooth operation of hydraulic equipment.

Contact us right now to get more information, professional advice will be supplied within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.