Brief introduction:

Sodium Petroleum Sulfonate Sulfonate Na 460 also called T702 is an oil-soluble, medium molecular weight refined sodium petroleum sulfonate with excellent emulsification and ease of formulation. Sulfonate Na 460 (T702) can be used as primary emulsifier or co-emulsifier formulations of soluble oils and semi-synthetic type metalworking fluid. Sulfonate Na 460 (T702) emulsifier provides excellent Excellent dispersing and wetting properties.

Chemical Name:

Sodium Petroleum Sulfonate

Package: 200kg/barrel, 1000kg/IBC Tank

Item | Specification | ||

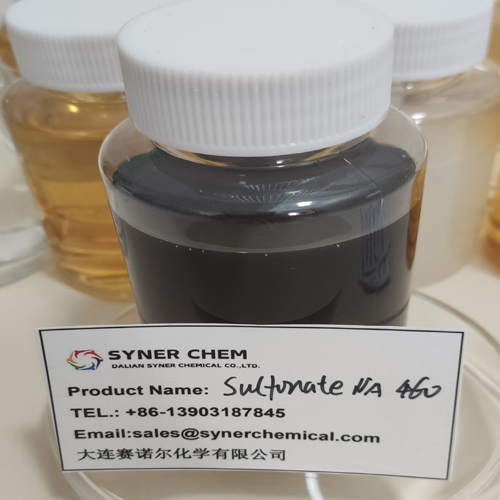

Appearance | Reddish Brown Clear Viscous Liquid | ||

PH(1%) | 7.00-9.00 | ||

Moisture % ≤ | 3.00 | ||

Molecular weight | 430 | 460 | 500 |

Assay % ≥ | 50.0% | 60% | 60% |

Conclusion | Qualified | ||

Application: for sodium petroleum sulfonate Sulfonate Na 460 (T702), there are main application as below:

1. Lubricant additives

Anti – wear and extreme – pressure performance: In lubricating oils, sodium petroleum sulfonate can form a protective film on the metal surface. When mechanical parts are in contact and under high – load and high – speed operation conditions, this film can effectively reduce friction and wear between metal surfaces, and prevent metal – to – metal direct contact, thereby improving the anti – wear and extreme – pressure performance of the lubricant. For example, in gear oils and engine oils, it helps to protect gears and engine components such as crankshafts and connecting rods.

Corrosion inhibition: It has good corrosion – inhibiting properties. The sulfonate molecules adsorb on the metal surface, isolate the metal from corrosive substances such as water and oxygen in the environment, and prevent the metal from being corroded. This is especially important for lubricating systems that may be exposed to humid air or other corrosive media.

2. Emulsifier in metal processing fluids

Emulsification of oil – water systems: In metal cutting fluids and metal – working fluids, sodium petroleum sulfonate can emulsify the oil phase and water phase. It reduces the surface tension between oil and water, allowing the two phases to mix evenly to form a stable emulsion. The emulsion – type metal – working fluid can play a good role in cooling, lubricating and chip – flushing during the machining process. For example, in the cutting process of lathes and milling machines, it helps to improve the surface quality of the workpiece and the service life of the cutting tool.

3. Rust – preventive agents

Surface protection: Sodium petroleum sulfonate can be used as a rust – preventive agent for metal surfaces. When applied to the surface of metal products such as steel sheets and machined parts, it forms a protective layer that inhibits the occurrence of rust. This is beneficial for the short – term or long – term storage of metal products, ensuring that the metal surface remains in a good state before the next processing or use.

Storage Notes: Sealed stored in cold, dry, good ventilated place, avoid high temperature and moist.

Syner Chem Sulfonate Na 460 Advantages: compared with the market other T702 products. our advantages as below:

What should be considered when you choose the right Products for metalworking fluid?

Compatibility with metalworking fluids: Ensure that the product does not have adverse reactions with other components in the processing fluid, resulting in a decline in the performance of the processing fluid.

Spectrum and efficacy of sterilization: According to actual needs, select a product that has a good inhibitory and killing effect on common microorganisms.

Applicable pH range: It should match the pH range of the metalworking fluid.

Safety: Including the health impact on operators and the friendliness to the environment.

Stability: Be able to maintain the stability of the active ingredients during storage and use.

Regulatory compliance: Select products that comply with relevant laws and regulations.

Contact us right now to get more information, professional advice will be supplied within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.